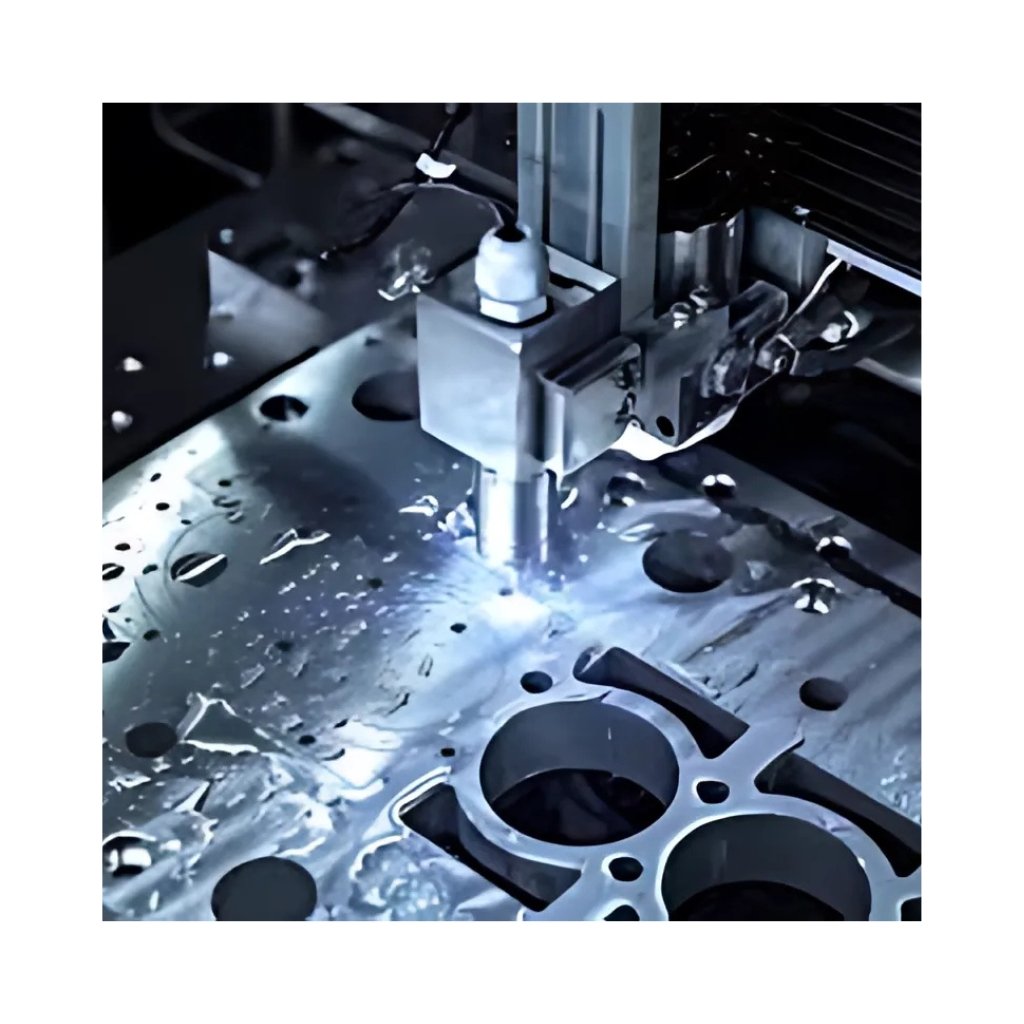

Precision Engineering

High-accuracy machining and forming processes ensure every automotive part meets tight tolerances and design integrity.

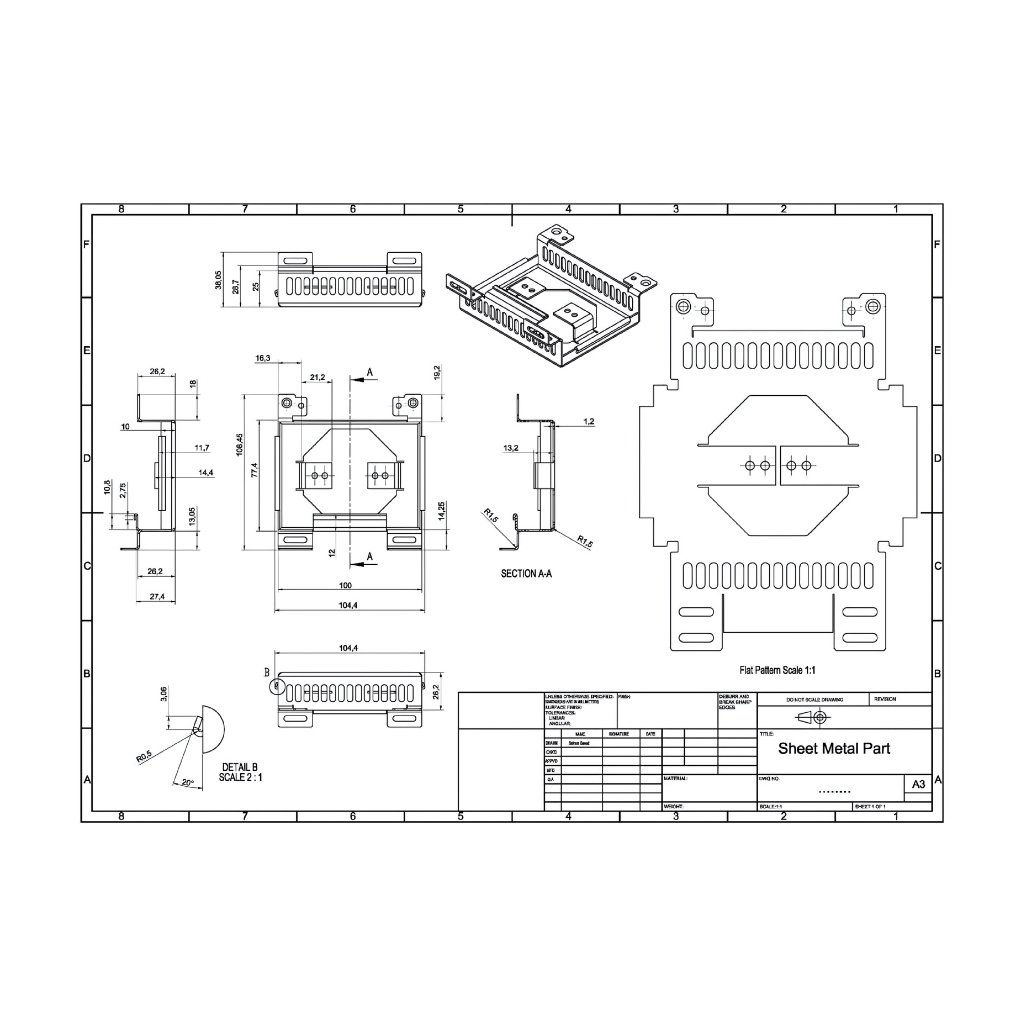

Tooling & Fabrication

Custom die, mold, and fixture manufacturing supports complex automotive components across body, chassis, and engine systems.

Innovation & Automation

Smart automation and robotics drive consistency, speed, and safety across our production floors.